| |

Fault Seal Analysis at Heart of Reservoir Modeling Workflow

Posted: 06 June 2005

Roxar has launched RMSfaultseal ™ , an easy to use, multi-platform fault seal analysis solution which will analyze fault zone properties within the integrated reservoir model workflow and export final results for reservoir simulation.

RMSfaultseal ™ ’s benefits to customers include better decision-making due to improvements in the reservoir model with fault properties fully incorporated; faster and improved history matching due to better fault property characterization; and increased productivity with RMSfaultseal ™ , a seamless part of the integrated reservoir workflow. RMSfaultseal ™ ’s benefits to customers include better decision-making due to improvements in the reservoir model with fault properties fully incorporated; faster and improved history matching due to better fault property characterization; and increased productivity with RMSfaultseal ™ , a seamless part of the integrated reservoir workflow.

RMSfaultseal ™ is fully integrated into Roxar’s industry leading 3D reservoir modeling solution, IRAP RMS ™ , bringing fault seal analysis into the mainstream of reservoir management. The results can be used directly with RMSflowsim ™ , a fully integrated black oil simulator within the reservoir simulation solutions portfolio, and RMSstream ™ , a single-phase streamline analysis tool that can be applied to geological-scale and upscaled simulation models.

RMSfaultseal ™ comes with a broad range of algorithms and calculation methods which can calculate fault zone permeabilities and transmissibilities for input to reservoir simulation.

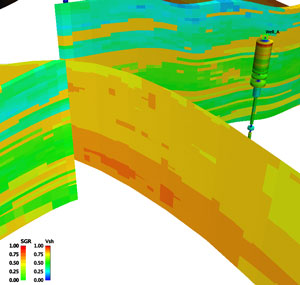

This includes: the module’s ability to create a number of fault rock property predictions including Shale Gouge Ratio (SGR), Shale Smear Factor, Clay Smear Potential, and user-defined SGR curves as well as the algorithms described in Manzocchi et al. (1999) and Sperrevik et al. (2002); the export of transmissibility or transmissibility multipliers to industry standard simulators; the ability to support stair-step gridding; and cell face visualization, which allows answers to be viewed and checked.

Roxar CEO, Sandy Esslemont, welcomed the launch of RMSfaultseal ™ : "For too long, fault seal analysis has tended to be a highly specialized, niche tool – an often overlooked part of reservoir modeling. Roxar is changing this today through the launch of an easy to use, integrated and feature-rich solution which sits at the very heart of reservoir modeling workflow. The result will be more geologically robust reservoir modeling, improved decision-making, history matching and productivity and the attainment of the ultimate goal – maximized reservoir performance."

As part of the future development of its fault seal and structural modeling capabilities, Roxar is partnering with Rock Deformation Research Limited (RDR), an established market leader in structural geology which operates as a consultancy company and research group based at the University of Leeds, England. Using the IRAP RMS ™ software platform, RDR is working with Roxar to further develop its fault seal analysis capabilities and calculation methods.

Today, 75% of all hydrocarbon-bearing traps are fault-related. Faults can break up communications between different layers within oil and gas reservoirs, as well as degrading communications across faults. For clastic fields worldwide, locating and analyzing fault seals have become an essential task. There is now broad and growing agreement within the industry that the correct characterization of fault seals is a crucial missing step in the reservoir modeling to simulation workflow.

Key benefits of RMSfaultseal ™ are:

- Improved Decision-Making . By taking fault properties into account when building the reservoir model, an improved reservoir model can be developed leading to better decision-making. RMSfaultseal ™ will also lead to quicker and improved history matching. In addition to the Manzocchi and Sperrevik methods in calculating permeability within the fault zone, Roxar’s fault analysis module also incorporates Shale Gouge Ratio (SGR) curves rather than just default curves. The result will be the ability to incorporate more customized information from one’s own oil & gas field and greater accuracy in the reservoir model developed.

- Faster Workflow & Increased Pr oductivity. RMSfaultseal ™ will be fully integrated within the workflow of Roxar’s reservoir modeling portfolio, IRAP RMS ™ . The result will be increased productivity and a streamlined workflow with fault seal analysis no longer a separate stand-alone activity that requires the extra efforts of exporting the model and importing back. The results of RMSfaultseal ™ can be used directly within IRAP RMS ™ ’s existing modules – in particular, RMSflowsim ™ , the RMS module that integrates dynamic reservoir data with the static model, and RMSstream ™ , which evaluates reservoir models and helps define flow paths.

- Ease of Use. RMSfaultseal ™ comes within an easy to use, 3D visualization environment, providing a comprehensive data interpretation and editing functionality. The module is able to create a number of fault rock property predictions including SGR, Shale Smear Factor, Clay Smear Potential, and user-defined SGR curves. Cell visualization will also allow answers to be viewed and checked.

- Flexibility . RMSfaultseal ™ offers full flexibility to the user with respect to which faults to analyze and which methods to utilize. The workflow and model realization concepts of RMSfaultseal ™ represent the ideal tool to test the effects of faults on different sedimentological/petrophysical models and to validate the flow properties and document the consequences for production.

RMSfaultseal ™ also allows for the export of transmissibility or transmissibility multipliers to other industry standard simulators. RMSfaultseal ™ operates on a wide variety of platforms, including SGI-IRIX, Sun Solaris, Linux and Windows.

IRAP RMS ª comprises 14 fully integrated software modules designed to help geologists, reservoir engineers and geophysicists to work together faster and more easily, to increase productivity from existing fields and to shorten the discovery-to-production lifecycle. Roxar creates value for its customers through its Reservoir Interpretation, Reservoir Modeling, Reservoir Simulation, Well and Completion, Pr oduction and Pr ocess Solutions and Consultancy Services.

Posted by Editor Pipeline Magazine

Information supplied by companies

or PR agencies who are responsible for content. Send press releases

to info@pipelinedubai.com |

|